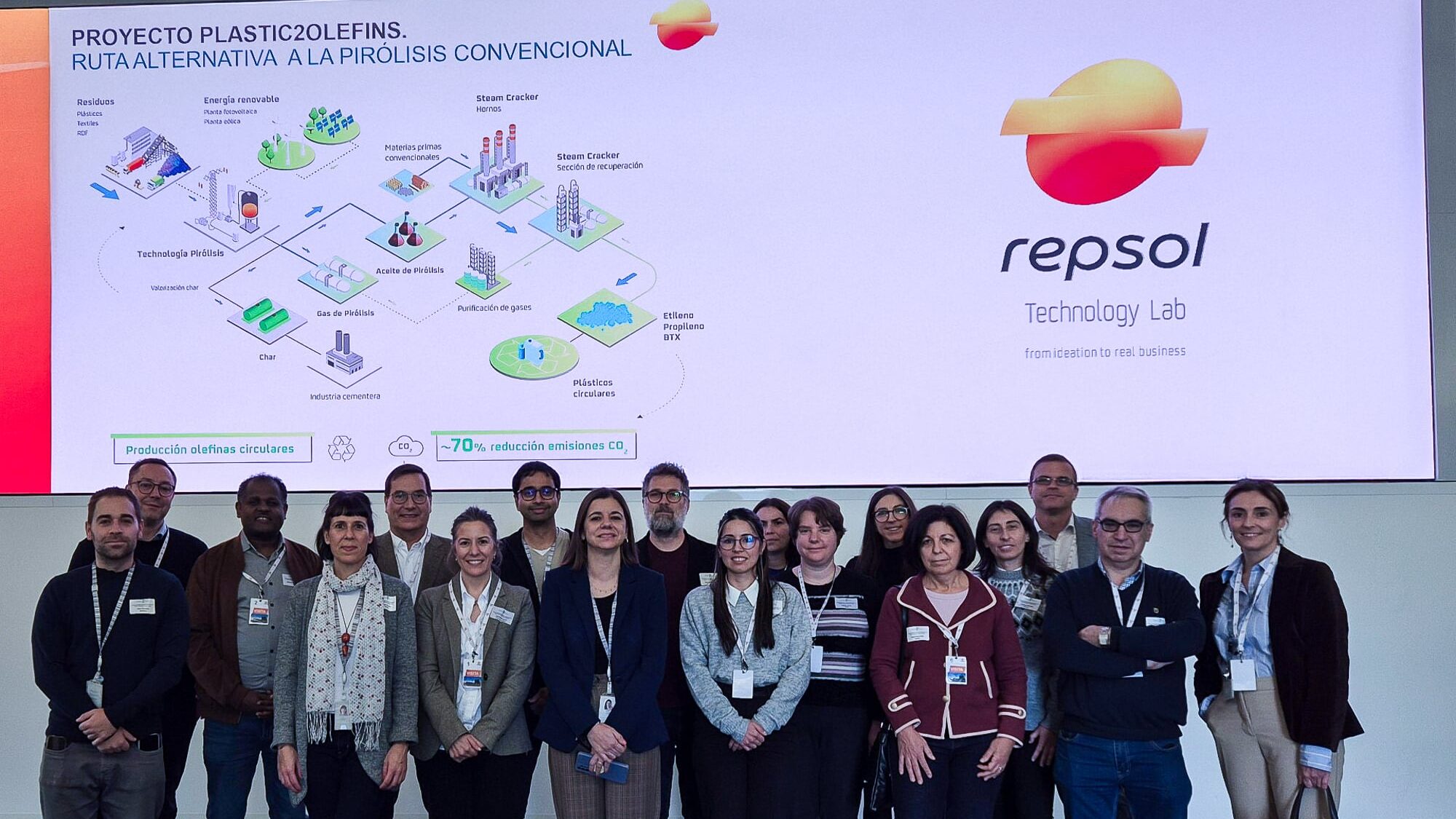

At the 8th General Assembly in Madrid, Plastics2Olefins partners gathered to push the boundaries of circular innovation and accelerate progress toward industrial-scale chemical recycling.

The Plastics2Olefins consortium met on 20 November 2025 for its 8th General Assembly (GA), hosted by Repsol at the state-of-the-art Repsol Technology Lab in Móstoles, Madrid.

The meeting brought together project partners from across Europe and Thailand to review progress, align on technical developments, and plan the next steps toward transforming plastic waste into high-value olefins.

With a full programme including work package presentations, in-depth discussions, and a guided pilot plant visit, the GA#8 marked another important milestone in the project’s journey.

Morning Highlights: Reviewing Progress Across Work Packages

The meeting opened with a welcome from the project coordinator Rebeca Yuste (Repsol) before partners presented updates from the last six months, results achieved, and upcoming activities.

The morning session featured contributions from all technical and management work packages (WP):

- WP1 – Project Coordination (PNO Innovation)

- WP2 – Pre-treatment and Pyrolysis Optimisation (Repsol)

- WP3 – Downstream Process Optimisation (CIEMAT)

- WP4 – Digitalisation and Renewable Energy Integration (Repsol)

- WP5 – Technical Integration and Engineering (Técnicas Reunidas)

- WP7 – Sustainability Assessment & Replicability (DTU)

- WP8 – Exploitation, Communication & Dissemination (SIN)

Partners discussed key achievements, remaining technical challenges, pilot progress, downstream optimisation tasks, sustainability modelling, and engineering design for the future demonstration plant.

Visiting the Repsol Technology Lab and Pilot Plant

A highlight of the day was the guided tour of the Repsol Technology Lab and the Plastics2Olefins pilot plant, offering partners a firsthand look at the technological advances driving the project.

- Read also: Presenting the Partners: Repsol Leads the Way in Chemical Recycling with Plastics2Olefins

Seeing the ongoing work on pyrolysis, gas cleaning, condensation systems, and process integration provided valuable insights into the next steps required for scaling the technology toward demonstration level.

Afternoon Deep Dive: Lessons Learned and Strategic Alignment

In the afternoon, partners engaged in an intensive review session covering Periodic Report learnings, Description of Action compliance, resource use by WP, and financial status across beneficiaries.

The open discussion format allowed partners to align on:

- Cross-WP technical dependencies

- Data needs for upcoming reports

- Key bottlenecks and research requirements

- Preparations for upcoming evaluations and project milestones

Reflecting on the work ahead, partners acknowledged both the complexity and the ambition of the project. As one participant noted:

“This is one of the complex projects with high ambition that needs detailed engineering work, good knowledge of techno-economics analysis, and deeper regulations.”

The session concluded with agreement on action points, next steps, and expectations to continue the project implementation.

Looking Ahead: Commitment to Collaboration and Impact

The 8th General Assembly underscored the strong collaboration and shared ambition across the Plastics2Olefins consortium. While significant progress has been made in pilot plant development, sustainability modelling, engineering design, and digital integration, partners also highlighted the need for intensified research and continued alignment.

- See also: Plastics2Olefins videos

The consortium remains committed to delivering a robust, scalable chemical recycling process capable of converting complex plastic waste into valuable olefins. This will contribute to Europe’s transition toward a more circular, resource-efficient, and climate-neutral future.