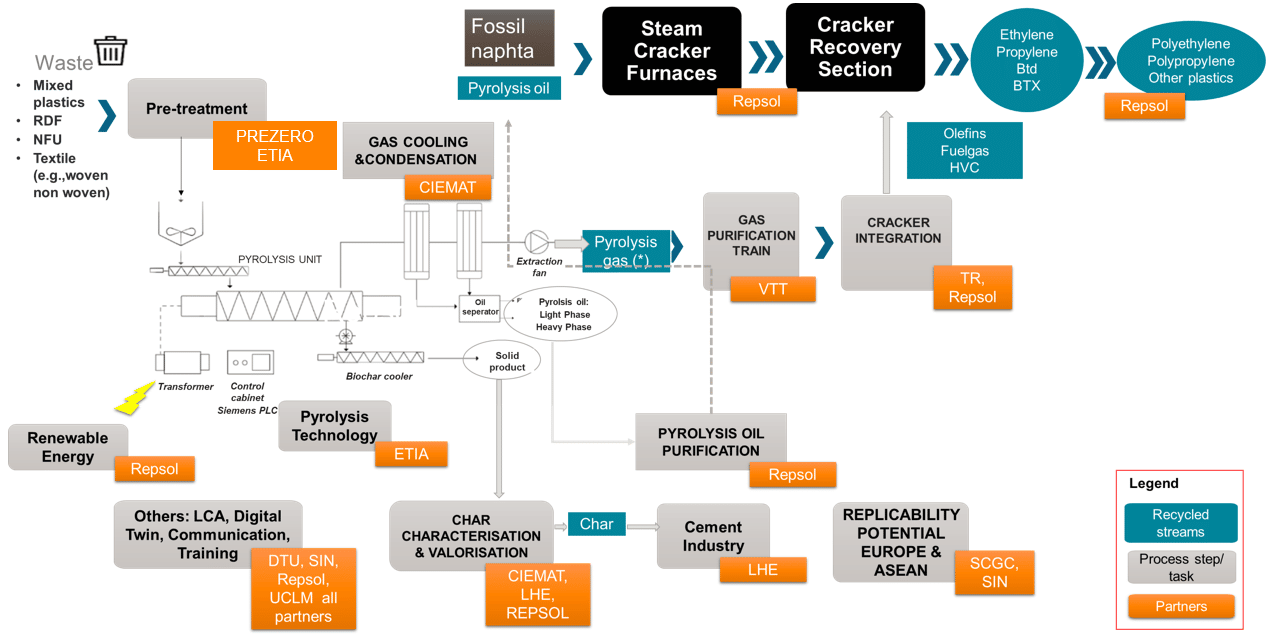

Plastics2Olefins will advance, integrate and upscale the high-temperature pyrolysis technology, the upstream and downstream process optimisation to recycle the unsorted plastic waste and for direct olefin production in an industrial environment, achieving TRL 7 by the end of the project. This will be done in two step process- performing testing and validation at pilot scale of 10kg/h, and then, designing, constructing operating a 1ton/h capacity demonstration plant at the premises of Repsol in Spain. The gas and liquid product fractions derived from the recycling of plastic waste will be further used in the petrochemical complex of Repsol, using the light olefins obtained in its polymerisation processes for polyethylene and polypropylene production closing the loop of plastic to plastic. The char produced will be valorised as an alternative sustainable solution to in cement production (instead of pet-coke). This will help to close the loop.

The techno-economic analysis for renewable energy integration will be performed and accordingly, the renewable energy supply will be integrated to electrify the pilot and demo plant. At the end, a concept will be delivered for 100% renewable energy integration. Also, a digital twin will be created based on the data inputs from the pilot and demo plant and suitable mathematical models of the process.