As one of Europe’s leading technical universities, the Technical University of Denmark (DTU) brings world-class expertise in sustainability assessment to the Plastics2Olefins project.

By applying advanced life cycle assessment (LCA) methods in Plastics2Olefins, project partner DTU helps ensure that the new process for chemical recycling of plastics delivers real, measurable environmental benefits.

A Technical University with Global Reach

The Technical University of Denmark (DTU) was founded in 1829 by H.C. Ørsted as Denmark’s first polytechnic institution. Today, it is ranked among Europe’s top technical universities and plays a central role in educating the next generation of engineers and researchers.

- Read also: Presenting the Partners: Técnicas Reunidas – Engineering the Future of Circular Solutions

DTU currently educates approximately 13,500 students and 1,600 postgraduates, and employs around 6,000 professionals. Its research and education activities span a wide range of engineering and technology disciplines, with strong links to industry, public authorities, and international partners.

Within DTU, the Section for Quantitative Sustainability Assessment focuses on applying quantitative methods to evaluate environmental sustainability across whole life cycles. This work includes life cycle assessment (LCA) and UN Sustainable Development Goals (SDG) assessments, with a strong emphasis on absolute sustainability perspectives through the DTU Absolute Sustainability Centre.

The section is recognised as a global leader in LCA-based method development, providing tools such as the well-known USEtox model. It offers strong research capabilities, cross-sector methods, and a stable PhD programme, while actively fostering collaboration across disciplines and sectors. Excellence lies in initiating new research fields, shifting paradigms from relative to absolute assessments, coordinating global scientific efforts, and translating LCA into practical applications.

DTU’s Role in Plastics2Olefins

The Plastics2Olefins project has an ambitious environmental objective: to significantly cut greenhouse gas emissions compared to current end-of-life options for plastics. In this context, rigorous sustainability assessment is essential.

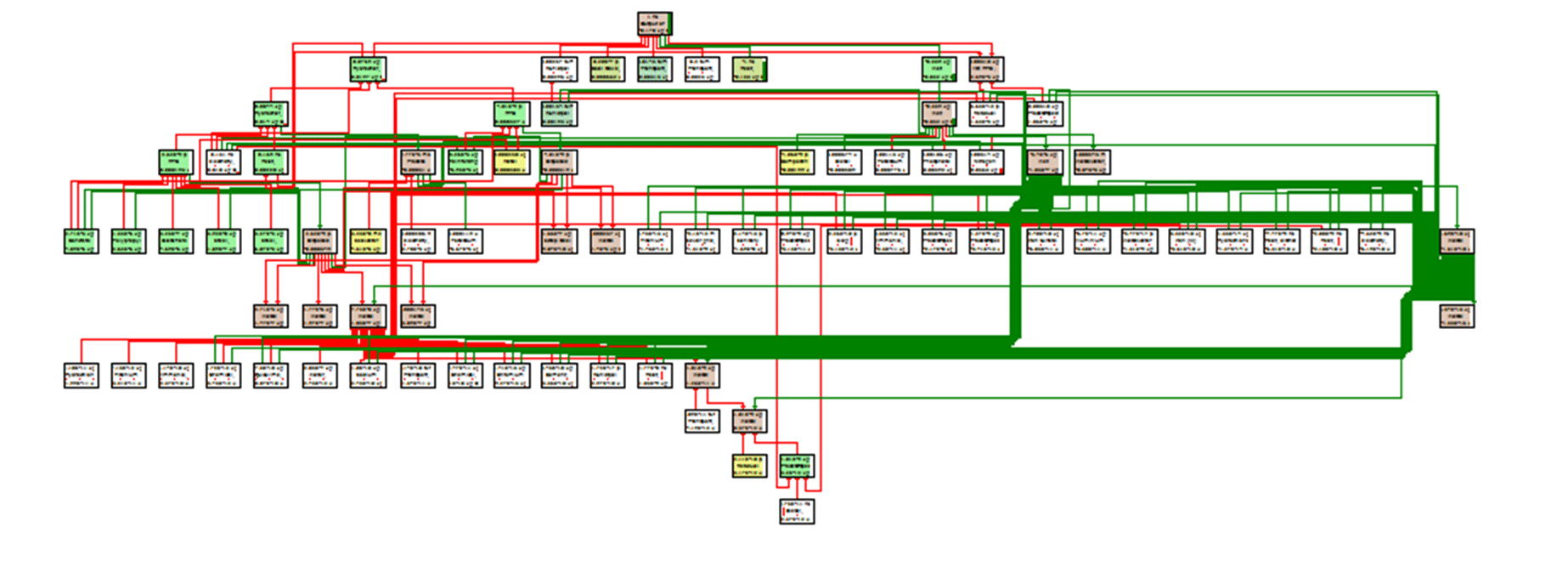

As part of Work Package 7 (WP7), DTU is responsible for conducting life cycle assessments of the Plastics2Olefins process at both demo and full scales, using data collected from partners across the consortium. This allows the team to evaluate the environmental performance of the new technology in a transparent and science-based way.

“Given that the project’s objective is to reduce greenhouse gas emissions by over 70% compared to the current end-of-life options for plastics, the knowledge of LCA is vital in Plastics2Olefins,” says Dr. Mikolaj Owsianiak, Senior Researcher at DTU.

A key part of the work is to compare the new Plastics2Olefins process with existing alternatives:

“The novel process will be compared against the currently predominant low temperature plastic pyrolysis to transparently evaluate potential benefits and tradeoffs,” explains Dr. Owsianiak.

DTU is also involved in the replicability study within WP7, which explores how the process might perform in different regional contexts. This is crucial because environmental impacts are influenced by local conditions such as energy mix, waste management systems, and industrial infrastructure.

“The optimal solution for plastic waste may not be the same between different locations,” notes Dr. Owsianiak.

Promising LCA Insights and Next Steps

The ongoing LCA work is already yielding valuable insights for the Plastics2Olefins consortium.

“The preliminary results of the LCA on the Plastics2Olefins demo scale process are promising within Spanish context,” says Dr. Owsianiak.

As the demo plant design and operation are further refined, remaining assumptions in the assessment will be updated when new data becomes available.

According to DTU’s Senior Researcher, the LCA indicates that the Plastics2Olefins process can offer advantages over benchmark pyrolysis in several key environmental impact categories:

“The LCA shows lower impacts than benchmark pyrolysis in several impact categories, including climate change and fossil resource use, but tradeoffs are predicted in terms of toxicity and mineral resource use due to the implementation of 95% renewable electricity.”

Even with these tradeoffs, the findings are encouraging for the project’s future:

“Nevertheless, the benefits are not only due to green energy use, which is encouraging for the further development of the process,” concludes Dr. Owsianiak.

By combining cutting-edge LCA methodologies with a strong focus on absolute sustainability, DTU helps ensure that Plastics2Olefins not only advances technological innovation, but also delivers genuine environmental benefits in the transition towards a more circular plastics economy.